60 Gallon immersed tube bitumen boiler

mounted on a fast tow trailer, with indicator

and reflectors built onto the frame.

A bucket step provided a safer height to

decant the bitumen.

This boiler was unique at its time using

a ‘kettle design’ firing the heat into tubes

within the pan that subsequently heated the

bitumen more effectively.

A family business established in 1950

Over the years Horrods have designed a range of different types, styles and mechanical handling

to provide solutions where clients have requested them for their projects.

Below are some of the examples that have been designed to make life easier!

Standard Asphalt & Bitumen Equipment

A Standard bitumen boiler mounted on a flat

top truck fitted with specialist heatshield to protect

the LPG cylinder, and a bucket step to the rear.

Designed to move the bitumen boiler around a site,

never on a road.

The Bitumen boiler itself has a half-hinged lid, with

an immersed outlet tap to decant the materials.

(below, a twin unit) designed for site use only.

The bucket heater was originally designed to replace the very dangerous pracise of operatives in

civil engineering, using a ‘camping stove’ to heat bitumen in buckets. Balancing basic buckets on this

exposed flame precariously, to use the materials for banding/bonding on roads/motorways in UK.

Since, it has become a very versatile, and far safer optio. Designed in the Horrod tradition, with safety first!

As with most designs, this product maintains the heat in the material necessary for the job when a larger

unit, such as an asphalt mixer, or hot air rubber melter, etc., are unable to be accomodated due to the

Used at sites with more confined space the material is conveyed from the ‘melter/mixer’

via a bucket (lidded buckets are also availble) to the heater which then maintains the

heat within the material until the operatives are able to use it.

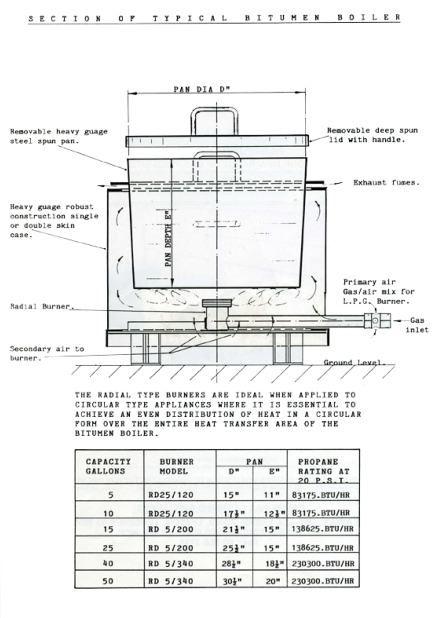

Standard Bitumen Boilers

10-50 Gallon Capacity are still utilised

within the area of roofing on smaller

projects.

These boilers are either single or

double skin cases the latter providing

a better shield to maintain the heat

within the pan.

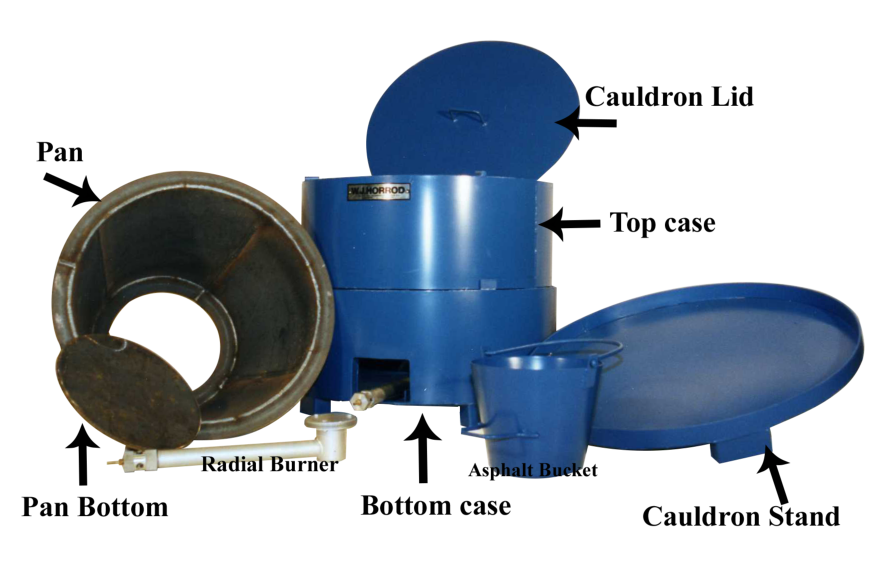

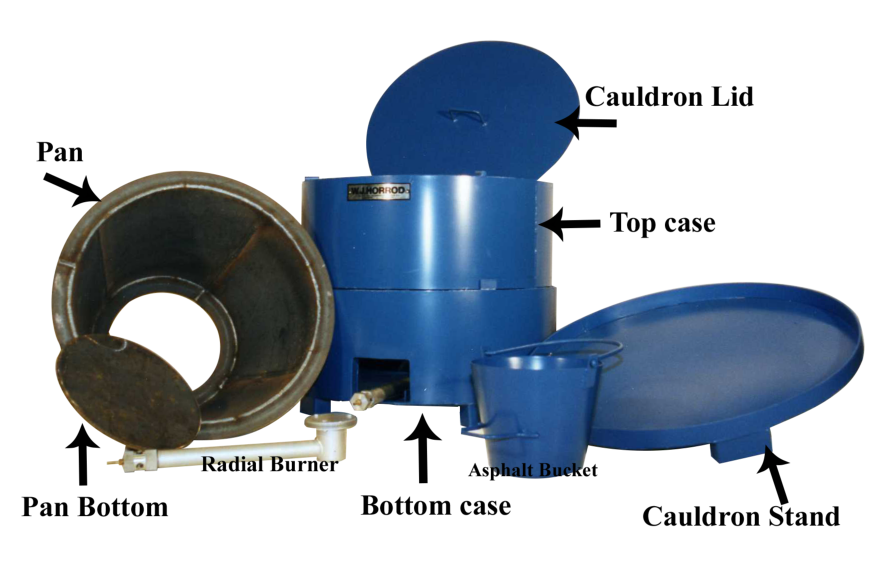

Asphalt Cauldron and accessories.

The 10½ cwt Cauldron (illustrated), is a 2 piece

case, housing a conical pan which is used

with a false pan bottom.

The sizes available:

2 piece case cauldrons: 10½ cwt | 4½ cwt

Single case 2½ cwt

Asphalt Patching Pot

As its name suggests, the patching pot is

a small portable unit that permits the user to

cover the smaller jobs/areas needed to finish

or even repair on site.

Standard Asphalt Bucket

The standard bucket provides a method of transport

for asphalt from a-b (pot/mixer/cauldron) to laying point.

The bucket is made from a heavy spun steel in a single piece

with a tipping handle at the midline, and the carry handle

being attached to lugs welded securely either side.

Special Asphalt Bucket (left)

This bucket is fortified with a striker bar and band

making it a lot more harder wearing.

Accessories Asphalt Equipment

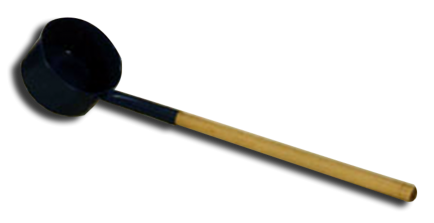

Bitumen Ladle

Used on smaller sites for decanting bitumen from a

boiler.

The crimple roller is a device used on laid hot asphalt

to create a tactile surface. It is a solid ‘roller’ with a

long fitted handle and reverse elevation bar.

Crimple Roller

Our bitumen boilers are used in many industries: Sterlising cutlery, Shellfish cooking, and even fishing bait in the form of boilies.

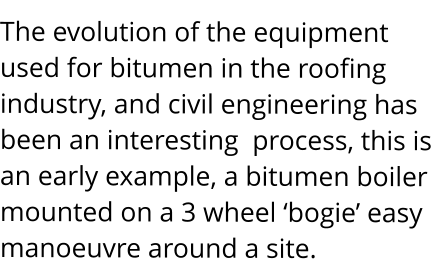

Specialist Bitumen Equipment (past and present)

Asphalt buckets can be

modified for special use.

Click on the images for user guides

A family business established in 1950

Over the years Horrods have designed a range of different types, styles and mechanical handling

to provide solutions where clients have requested them for their projects.

Below are some of the examples that have been designed to make life easier!

Standard Asphalt & Bitumen Equipment

A Standard bitumen boiler mounted on a flat

top truck fitted with specialist heatshield to protect

the LPG cylinder, and a bucket step to the rear.

Designed to move the bitumen boiler around a site,

never on a road.

The Bitumen boiler itself has a half-hinged lid, with

an immersed outlet tap to decant the materials.

(below, a twin unit) designed for site use only.

Standard Bitumen Boilers

10-50 Gallon Capacity are still utilised

within the area of roofing on smaller

projects.

These boilers are either single or

double skin cases the latter providing

a better shield to maintain the heat

within the pan.

Accessories Asphalt Equipment

Our bitumen boilers are used in many industries: Sterlising cutlery, Shellfish cooking, and even fishing bait in the form of boilies.

Specialist Bitumen Equipment (past and present)